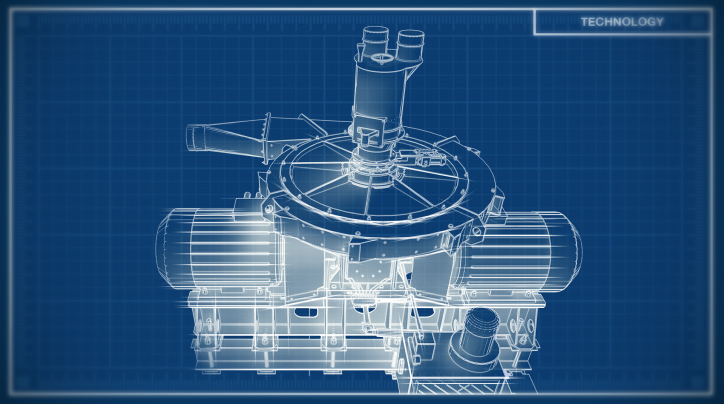

The technology of Finegri is based on an original grinding principle, which allows to obtain a finished product with a high nanoparticle content and a high degree of homogeneity, ensuring a high matricity of the package.

Our specialists have developed a new type of robust and multi-functional grinding equipment that enables producing super-fine powders out of various feedstock, while simultaneously reducing specific energy consumption.

Advantages of Finegri technology:

- mechanical grinding method, without any additional input, such as water, air, heated steam, etc., which ensures low specific energy costs;

- high performance;

- no end product classification: the finished powder is not fractionated (dispersed), thus the powder is not depleted due to a reduced variety of particles having different sizes, and the product has the optimum particle distribution suitable for multiple purposes;

- feedstock’s plate-like structure is preserved in finished powders;

- high homogeneity and uniformity (matrix particle packing) of the end product;

- the end product contains no metal parts, i.e. the output has the same purity specifications as the feedstock does;

- our technology meets the most stringent environmental regulations, i.e. no dust emissions, and 99.9% exhaust air purification.

The company has the ability not only to strictly adhere to customers' requirements in terms of granulometric parameters, but also to execute individual orders for particle size distribution parameters according to technical specifications.