The entire initial ore feed and pre-grinding system is equipped with an air aspiration system, which enables complete air purification in the industrial process.

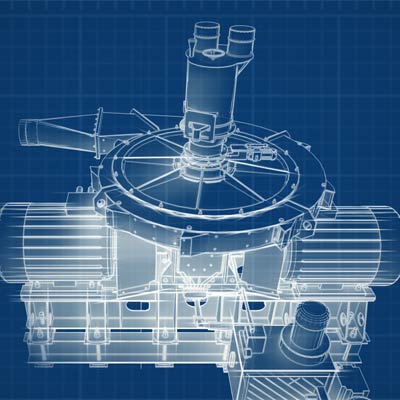

Finegri’s gridding system does not require any additional air intake. The system only uses ambient air fed into the pre-grinded product from the atmosphere.

Thereafter, fine grinding takes place, and the end product goes to the silo group equipped with the aspiration and filtration system for complete air purification in the fine grinding area.

In the packing section, silos containing the end product are connected to packaging machines that automatically package the product into multi-layer perforated paper bags with a polyethylene insert and polypropylene big bags. The entire process line is secured against emissions by the aspiration system. Next, bags are conveyed to the palletizer, where they are stacked on pallets, and the pallets are automatically wrapped with a polyethylene film.

The process line management is fully automated, and the key control parameters are displayed on the central console and doubled by the central computer, which protects the entire system from the “human factor”, automatically records the key figures, analyses them, and (where necessary) adjusts the parameters.

The quality laboratory ensures quick and objective control of the feedstock (ore) and end product (powder).