Using talc to manufacture cordierite ceramics is especially relevant in the ceramics industry. Cordierite ceramics are a high-temperature material with excellent thermal properties.

- Cordierite ceramics normally comprise the following key components:

- Talc: talc is the key feedstock for cordierite structure formation.

- Kaolin: kaolin, also known as kaolin clay, is added together with talc to form cordierite ceramics. It ensures material’s structural strength and contributes to the formation of its crystalline lattice.

- Aluminum: aluminum as an oxide is a mandatory component for cordierite structure formation. It contributes to the ceramics’ crystalline lattice.

- Other additives: the cordierite ceramics manufacturing may also use other additives, such as silicon dioxide or other metal oxides to improve certain ceramics properties, e.g. their thermal stability or mechanical strength.

The components are mixed together in certain proportions, after which the material undergoes firing at high temperatures. Firing and subsequent cooling result in the formation of cordierite structure in ceramics, which provides ceramics with unique thermal properties, including a low coefficient of thermal expansion and high thermal resistance.

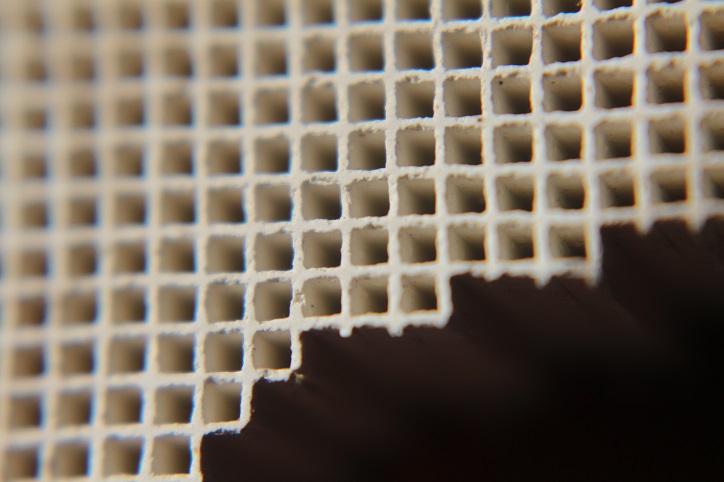

Cordierite ceramics are widely used in high-temperature and heat-insulating products, such as industrial furnaces, burners and heat insulating materials.

Below are some aspects of talc application in this process:

- Cordierite structure formation: talc is one of the main feedstock components for cordierite ceramics creation. It contains the necessary chemicals, which, when fired, get transformed into a specific cordierite crystalline structure. This is the key process that enables creating a material having outstanding thermal properties.

- Low coefficient of thermal expansion: cordierite ceramics have a very low coefficient of thermal expansion, which makes them tolerant to rapid temperature changes. This is relevant where ceramics are used in high-temperature and thermally stressed environments.

- Thermal resistance: talc-based ceramics have outstanding thermal resistance and tolerance to high temperatures. They may be used in various areas and products that require high temperatures, e.g. in industrial furnaces, burners and heat insulating materials.

- Electrical insulation: cordierite ceramics also have great electrical insulation properties. This makes them a valuable material for electrical products, which require high level of insulation and low current loss.

- Mechanical strength: talc-based ceramics have fair mechanical strength and resistance to wear and tear. This makes them resistant to mechanical impacts and damages, which is relevant for material’s durability and reliability.

Using talc to manufacture cordierite ceramics is an important process in the ceramics industry, which enables producing a material with unique thermal properties and outstanding performance at high temperatures.